The Difference Between Soldering, Brazing, and Welding - Solder Series: Ep. 2

In this week's episode of the SRA Solder Lab we cover the differences between soldering, brazing, and welding. Tune the last Thursday of every month at 12pm for more soldering tips and tricks!

The Difference Between Soldering, Brazing, and Welding - Solder Series: Ep. 2

Soldering, Brazing, and Welding Differences

This section discusses the distinctions between soldering, brazing, and welding based on temperature requirements, tools used, and the process of joining metals.

Temperature as a Determining Factor

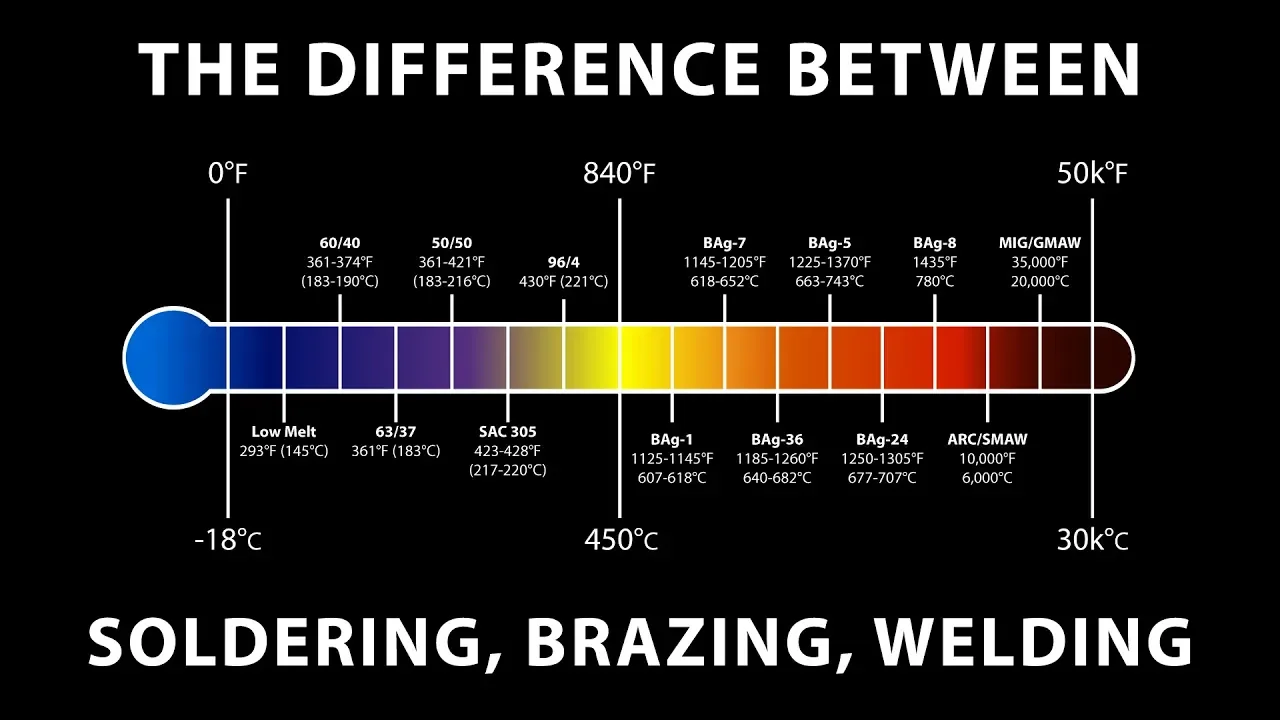

- Soldering involves melting alloys below 840 degrees Fahrenheit.

- Brazing or hard soldering occurs above 840 degrees Fahrenheit.

Tools Used in Different Processes

- Brazing requires high temperatures necessitating a torch or furnace.

- Soft soldering can be done with a regular soldering iron or heat gun.

Process of Joining Metals

- Solder has a lower melting point than the metal in soft and hard soldering processes.

- In welding, workpieces are melted along with filler metal to form a weld pool through fusion.

Key Takeaways

- Temperature range is crucial in distinguishing between soldering, brazing, and welding processes.

- The melting range of the solder depends on the alloy used, varying with different mixtures of metals having distinct melting points.